Answered by: Dane Ross

Most people in the non-destructive testing field know what magnetic particle inspection is, but few know where it originated from. For those of you who don't know what magnetic particle inspection is, it is a non-destructive testing process used to detect surface and slight subsurface discontinuities in ferrous materials, which are materials easily susceptible to magnetism. A part made out of such a material is magnetized and magnetic particles are applied to the part. Any discontinuities on or close to the surface of the part will create a break in the magnetic field, which will attract the magnetic particles. An area of accumulated particles form an indication, and reveal a discontinuity. Sounds exciting, doesn't it? But the real question is where did all of this start? It's not like on the 8th day God created the Magnaflux yoke...so how did magnetic particle inspection evolve to where it is today?

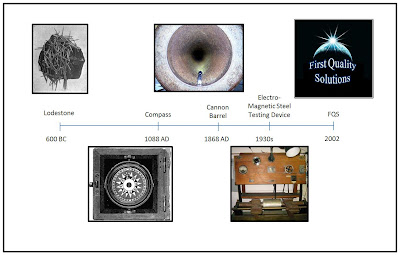

This is where the real intrigue starts because the first observations of magnetism date back more than 2500 years and this is where the history of our modern magnetic particle inspection begins. The Chinese observed that a "lodestone" or a naturally magnetized piece of magnetite had the power to attract pieces of iron to it. Around 1088 A.D. they found that if a needle that had been magnetized by stroking it across a lodestone was suspended it would point north and south. It could therefore be used to improve the accuracy of navigation, thus inventing the compass. Fast forward to 1868 when it was observed that a compass needle jumped when passed over a crack in a magnetized cannon barrel, and could therefore be used to inspect for cracks. In the 1930's, by observing iron filings on magnetized parts, patterns in the filings allowed for the first visualization of the magnetic field or "magnetic lines of flux." These patterns were able to reveal discontinuities on the surface of the parts, thus creating magnetic particle inspection.

From that point forward, ways to improve on these principles have been developed. Now AC or DC current can be used to establish a magnetic field in parts being inspected. Improvements in how to properly identify discontinuities have evolved from compass needles and iron filings to detection media such as iron powders and iron particles suspended in various liquids. Color coding these types of media also improved visibility and contrasting on test parts to make identification of discontinuities easier. The introduction of florescent iron particles and UV light increased sensitivity and further advanced these principles, thus creating another variable in aiding to identify discontinuities. Although it has been thousands of years since the first observations of magnetism, the basic principles remain the same but every year brings new innovations in the ever evolving field of non-destructive testing.

Dry Magnetic Particle Inspection

Wet Florescent Magnetic Particle Inspection

No comments:

Post a Comment