Answered by: Kevin Kissig

There is no one type of inspection that we perform more than any other type; we perform magnetic particle inspections on pumps and gears on an almost daily basis, and several times each year we routinely inspect headers, piping, fans and tanks, but if there is an inspection we've really perfected over the years, it would be boiler waterwall ultrasonic thickness inspections.

Waterwall inspections are generally the first inspection we perform during a power plant maintenance outage, and the results usually precede waterwall panel replacements. Therefore, the faster we can provide the results of this inspection, the faster our customers can begin panel replacements. As such, we've always looked for ways to improve the efficiency of this inspection.

Over the years, we've upgraded our equipment and experimented with different transducer types to provide the best results possible. We've also done extensive tests on different couplant mediums and application methods. We've transitioned from manually applied grease (messy and timely to clean), to mechanically applied oil-based couplants (prone to equipment failures and also requires post-inspection cleaning), and finally began using a manually applied water-based couplant that simply evaporates off the tubes after the inspection (no clean-up time required).

Our reports have also evolved over the years to provide the most detailed and well-organized information possible. Details and formatting have been adjusted over time, and the final reports are an invaluable tool for our customers to make informed decision at the moment as well as for planning future repair areas.

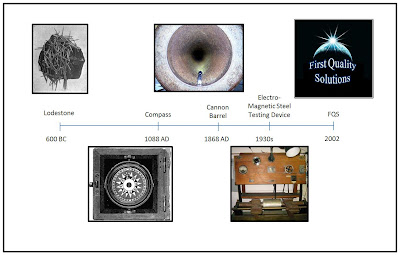

2002 Waterwall Survey (Upper) & 2012 Waterwall Survey (Lower)

Finally, our inspection team is extremely experienced in regards to this inspection. The waterwall inspection team has been working together for years, and each member of the team is well-aware of his or her responsibilities and duties during a boiler waterwall inspection. The team performs as a well-oiled machine, and what used to take several days in prep, inspection, and reporting time, has been reduced to a couple of shifts. It is an inspection that is extremely familiar to us and one that we are exceptional at performing, and it is an inspection that we continue to improve on every time we perform it.